Services

- Home

- Services

PCB

RE-ENGINEERING

Keep your equipment supported

DIGIHI Can Extend the life time of your critical manufacturing equipment. Our team can increase the availability and reliability for the declining or obsolete OEM. Our team of experience can extend the live and insure contained functionality of your systems. Also DIGIHI can develop your the existing systems and add more enhancement to keep your system reliable.

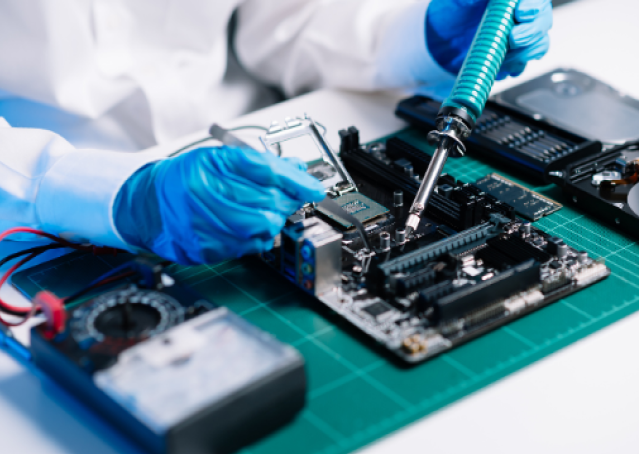

PCB RE-ENGINEERING

Keep your equipment supported

DIGIHI Can Extend the life time of your critical manufacturing equipment. Our team can increase the availability and reliability for the declining or obsolete OEM. Our team of experience can extend the live and insure contained functionality of your systems. Also DIGIHI can develop your the existing systems and add more enhancement to keep your system reliable.

What Is The Re-Engineering?

Re-Engineering of PCB’s

( Printed Circuit Boards) is a process by which we replicate the function and specification of an original printed circuit board. The re-engineering of PCB is utilized for a variety of important applications across multiple fields. The Most common uses include:

1- Repair and Maintenance

When the original documentation is unavailable, re-engineering helps repair and maintain equipment with obsolete or legacy PCBs, identifying and.

2- Redesigning Obsolete PCBs

Creating new versions of outdated PCBs to ensure continued availability and functionality of older systems and finding replacements for discontinued.

3- Cost reduction and enhance the performance

Redesigning PCBs to reduce manufacturing costs or optimize for newer, cheaper components. Modifying existing PCBs to improve performance, add new.

4- Failure Analysis

Investigating failed PCBs to identify design or manufacturing defects and improve future designs.

5- Research Projects

Analyzing existing designs to explore new concepts, technologies, or engineering practices.

6- Vulnerability Analysis and Investigating tampered

Identifying potential security vulnerabilities in hardware for cybersecurity purposes. Tamper Investigation or counterfeit electronics to understand modifications and ensure authenticity

7- Diagnostics and Problem solving

Through re-engineering, you can identify defective components, analyze failure, understand environmental impact, and through that, engineers can identify corrosion,

Benefits of Re-Engineering

Reduced Downtime:

Quickly diagnosing and solving issues reduces the downtime of critical systems.

Cost Savings:

Effective problem solving can prevent costly recalls, repairs, and replacements.

Improved Reliability:

Addressing and fixing issues leads to more reliable products and fewer failures in the field.

Research and Development

Research and Development (R&D) in reverse engineering involves analyzing existing products to understand their design and functionality. This process helps engineers uncover the principles behind a product, identify areas for improvement, and develop new solutions. R&D not only enables the replication of technologies but also drives innovation by refining existing processes and creating new products that enhance performance and competitiveness.

Research and Development

Research and Development (R&D) in re-engineering involves analyzing existing products to understand their design and functionality. This process helps engineers uncover the principles behind a product, identify areas for improvement, and develop new solutions. R&D not only enables the replication of technologies but also drives innovation by refining existing processes and creating new products that enhance performance and competitiveness.

PCB ASSEMBLY

PCB Assembly in re-engineering focuses on reconstructing and analyzing electronic circuits. Engineers examine the layout and connections of components to understand the PCB's operation. This includes sourcing components, replicating circuit designs, and reassembling the board. The process ensures that the replicated product matches the original specifications and performance standards, while also identifying any potential design improvements.

PCB ASSEMBLY

PCB Assembly in re-engineering focuses on reconstructing and analyzing electronic circuits. Engineers examine the layout and connections of components to understand the PCB's operation. This includes sourcing components, replicating circuit designs, and reassembling the board. The process ensures that the replicated product matches the original specifications and performance standards, while also identifying any potential design improvements.

Get In Touch With Us